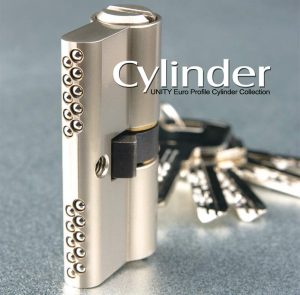

No matter what kinds of products we purchase, there is a common question for all, that is, “How to Find the Right One with Good Quality”? We will also meet some problems after a period of use of a euro lock cylinder and do not know how to deal with it. As a professional manufacturer of door hardware, we will share with you some information concerning problems of euro lock cylinders. These problems may easily happen during the production to influence the quality as well as the function of the cylinder. Hope this article can bring you some tips and guides when the purchase and use of euro lock cylinders.

For the problems that always happen when doing “Surface Treatment” of the euro lock cylinder

Problem 1: The electroplating quality is not good, and there are electroplating rust spots

Reasons:

A: The electroplating quality is not good.

B: In summer, assemblers have sweaty hands, which contaminates the surface of the lock cylinder’s housing.

Problem 2: Surface bumps, scratches, plating peeling, blistering, internal corners, blackening, yellowing, and other problems.

Reasons:

A: Bad quality coating or plating. The pretreatment before plating is not good, there is oxidation in the heat treatment process of the cylinder, the surface is not treated well before electroplating, then the surface of the original part and the electroplating layer cannot well combined. Another situation is that the electrolyte concentration and electroplating current and voltage are not well controlled during the electroplating process, which causes uneven coating and peeling.

B: The concentration of the antioxidant agent after electroplating is insufficient, and the coating reacts with air moisture/oxygen after storage.

The product is not completely dried, or the storage environment is not good, which results in oxidation of the lock cylinder.

For the problems concerning its function/performance

Problem 1: The key is tight, turning tightly and not flexible when you insert it

Reasons:

A: There are burrs on the key.

B: The tolerance of the marbles is too large.

Problem 2: Virtual opening: The key can be turned, but the dial does not move, the mortise lock body fail to open.

Reason: the horn is too short, or the key is too short

Problem 3: The cylinder core does not turn.

Reason: The key has extra attachment, or there is debris inside the lock cylinder.

Euro lock cylinder maintenance tips

- When the lock is in use, do not use any liquid oils such as edible oil as a lubricant on a regular basis (half a year or once a year) or you cannot smoothly insert or unplug the key, please avoid grease lubricant which will cause the cylinder core not turn normally. What we suggest is, use a pencil lead to paint the key, then insert the lock cylinder and turn it a few times for good lubrication.

- In addition, professional lubricants and rust inhibitors for locks are also available. Some zinc alloy and copper lock cylinders will find “spots” after being installed on the door for a long time. This phenomenon is not rust, but oxidation. If this happens, just spray it with surface wax You can remove the spots.

UNITY Hardware Ltd. Logo-professional architectural door hardware manufacturer

UNITY Hardware Ltd. Logo-professional architectural door hardware manufacturer